Ensuring Consistent Quality

From Raw Material to Final Product

At FidStrong, quality is not just a checkpoint — it is built into every step of our production, from raw material selection to finished product testing. We follow international standards and maintain strict quality control to ensure every batch meets or exceeds project requirements.

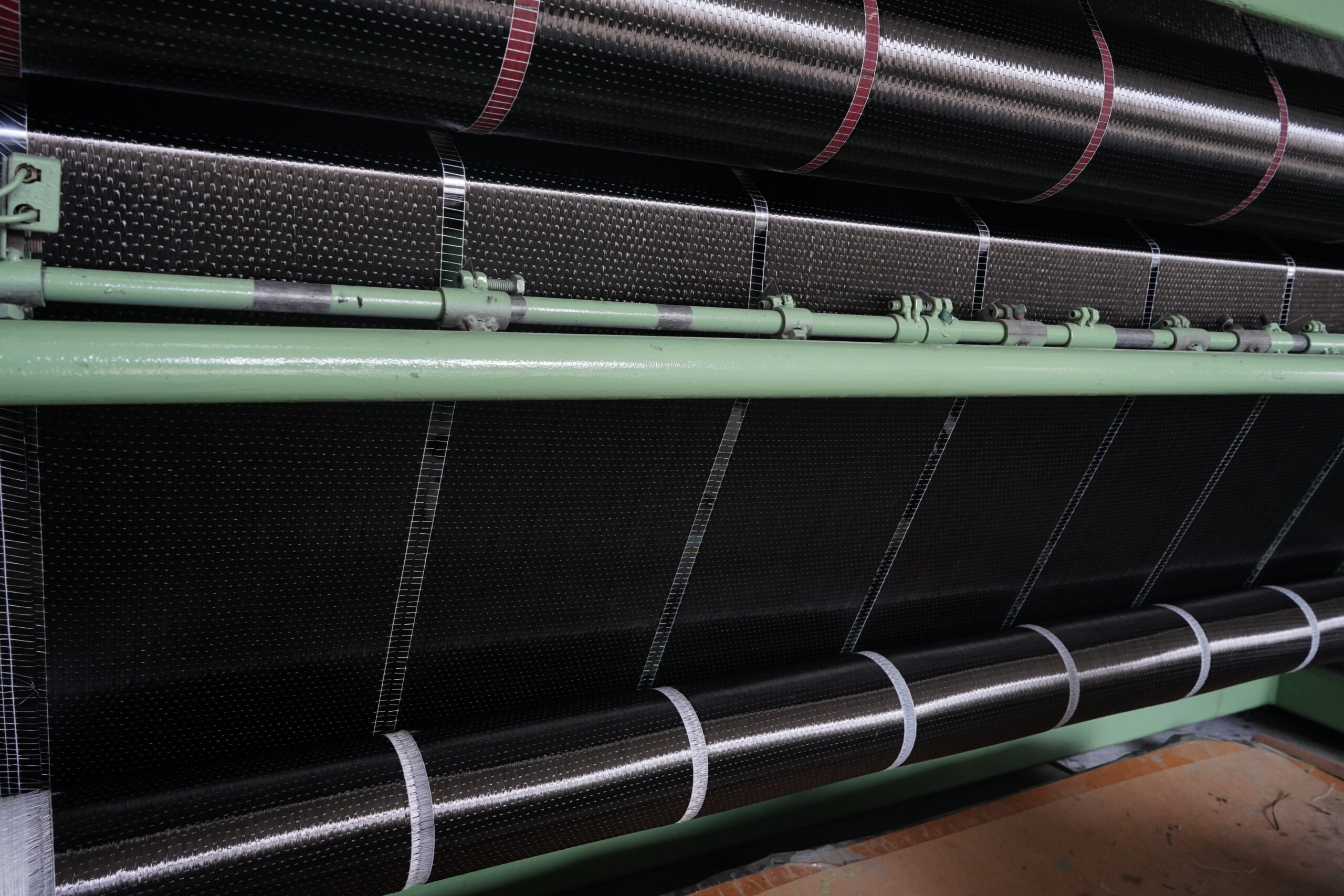

Raw Material Inspection

At Fidstrong, we understand that the foundation of superior carbon fiber products lies in the quality of raw materials. That’s why we implement rigorous inspection protocols and source exclusively from trusted global brands.

- Strict supplier selection with long-term partnerships

- Batch-by-batch incoming material inspection

- Key parameters tested: purity, viscosity, strength

- Traceability system for all incoming materials

- Certified raw materials from global brands

Production Process Control

At Fidstrong, our production process is meticulously controlled to ensure the highest quality in every product. From standardized procedures to advanced monitoring systems, we maintain unwavering standards throughout the manufacturing cycle. This dedication guarantees consistent performance and reliability in all our carbon fiber solutions.

- ISO 9001:2015 certified factory

- Standardized mixing, weighing, and batching procedures

- In-process monitoring: temperature, timing, ratio accuracy

- Trained technicians and automatic error-prevention systems

Quality Assurance

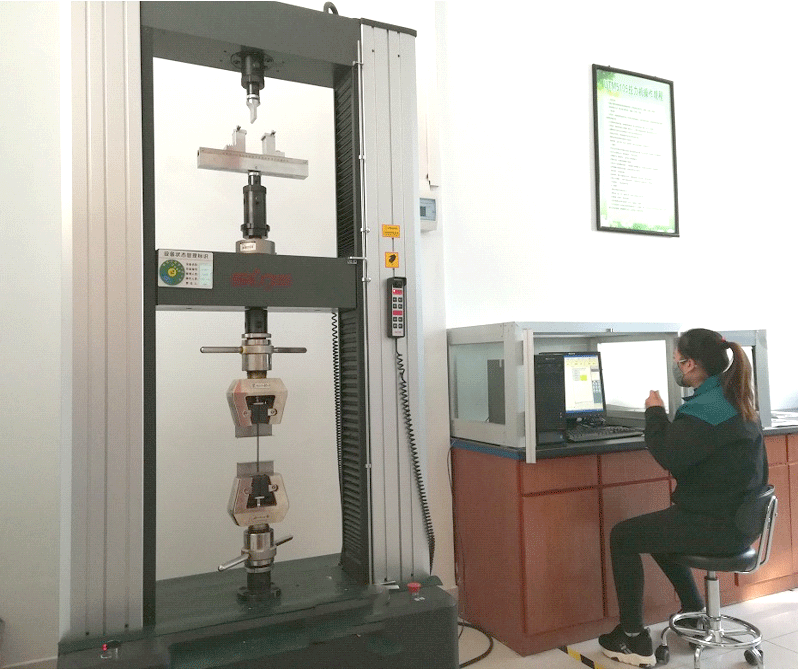

In-House Testing Capabilities

At Fidstrong, we maintain a state-of-the-art in-house laboratory for comprehensive mechanical and chemical testing. Our routine tests include tensile strength, bond strength, shear, and compression, ensuring each batch meets our stringent quality standards. We also conduct aging, fatigue, and durability simulation tests. Each product comes with an internal QC report and product code for traceability. Third-party testing and compliance are available upon request.

Finished Product Inspection

At Fidstrong, our finished product inspection is the final safeguard of our commitment to quality. We ensure that every product meets our stringent standards before it reaches our customers, reinforcing our reputation for excellence in the construction industry.

- 100% Visual Inspection Before Packaging

- Random Sampling for Destructive and Non-Destructive Tests

- Packaging Integrity and Labeling Checks

- Shelf Life Verification and Storage Condition Control